Nā Pono a me nā Noi o nā Paipu Welded Spiral i ka ʻoihana hou

Hoʻolauna:

Ma nā ʻoihana e ulu mau nei o ka ʻenekinia a me ke kūkulu ʻana, ka hoʻohana ʻana opaipu wili i hoʻopaʻa ʻiaKe lilo nei kēia mau paipu palupalu a paʻa i mea kaulana loa. Ua komo kēia mau paipu palupalu a paʻa i loko o nā ʻoihana like ʻole, e hōʻoia ana he hopena kipi no nā ʻano noi like ʻole. Ma kēia pou blog, e nānā pono mākou i nā pono kupaianaha i hāʻawi ʻia e nā paipu wiliwili a e ʻimi i kā lākou mau noi like ʻole i ka ʻoihana hou.

Waiwai Mīkini

| papa kila | ka ikaika hua haʻahaʻa loa | Ikaika tensile | Ka hoʻolōʻihi iki ʻana | Ka ikehu hopena haʻahaʻa loa | ||||

| Mānoanoa i kuhikuhi ʻia | Mānoanoa i kuhikuhi ʻia | Mānoanoa i kuhikuhi ʻia | ma ka mahana hoʻāʻo o | |||||

| <16 | >16≤40 | <3 | ≥3≤40 | ≤40 | -20℃ | 0℃ | 20℃ | |

| S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 27 | - | - | |||||

| S355J0H | 365 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 27 | - | - | |||||

| S355K2H | 40 | - | - | |||||

1. He aha ka paipu wili i hoʻopaʻa ʻia?

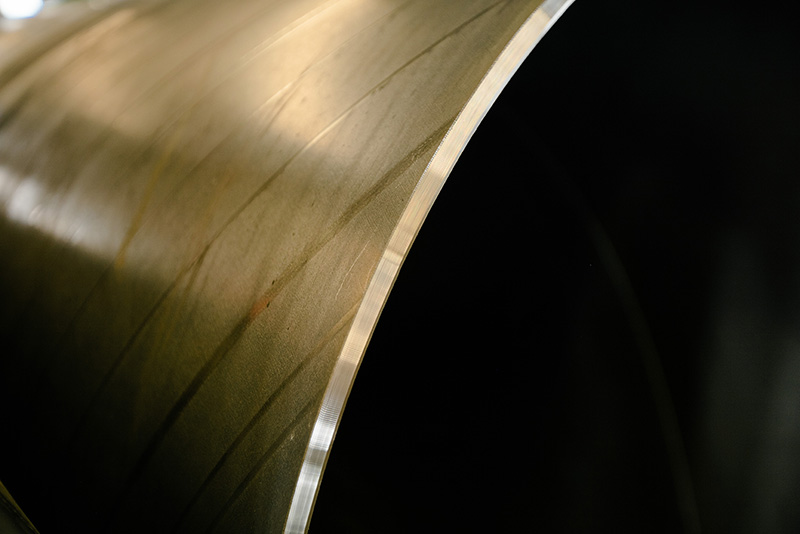

Paipu wili i hoʻopili ʻia, e like me ka inoa e hōʻike nei, ua hana ʻia ma ka ʻōwili mau ʻana i ke kila kila a me ka hoʻopili ʻana iā ia ma kona lōʻihi e hana i kahi paipu wili. Hōʻoia kēia ʻenehana hana i ka ikaika a me ka pono, e hana ana i kēia mau paipu kūpono no nā noi koi.

2. Nā pono o ka paipu wiliwili i hoʻopaʻa ʻia:

2.1 Ikaika a me ke kūpaʻa:

ʻO ke kaʻina hana kuʻihao wili e hāʻawi maoli i ka paipu i ka ikaika kiʻekiʻe. ʻAe kēia iā lākou e kū i nā kaomi kūloko kiʻekiʻe, nā ukana kaumaha a me nā mahana koʻikoʻi. No laila, hoʻohana nui ʻia lākou i nā ʻoihana kahi e koʻikoʻi ai ka pono o ke kūkulu ʻana.

2.2 Ke kūpaʻa ʻana i ka palaho:

Loaʻa nā paipu wiliwili i hoʻopaʻa ʻia i loko o nā ʻano mea like ʻole, me ke kila kila a me nā mea hoʻohuihui pale i ka pala. ʻO ko lākou kūpaʻa i ka pala e kūpono ai lākou no nā noi ma nā ʻoihana kemika, ʻaila a me ke kinoea, a me ka mālama wai. Hoʻolōʻihi lākou i ke ola lawelawe a hōʻemi i ka pilikia o nā leaka a me ka manawa downtime.

2.3 Ka pono o ke kumukūʻai:

Hāʻawi ka wili wili i nā pono kumukūʻai i hoʻohālikelike ʻia me nā ʻano hana paipu kuʻuna. ʻO kēia ma muli o ka emi ʻana o ka manawa hana a me ka hoʻemi ʻana i ka hoʻohana ʻana i nā mea. Eia kekahi, ʻo ka maikaʻi o ke ʻano o nā paipu wili wili e ʻae ai i nā hoʻolālā maʻamau a me nā hoʻonā i hana ʻia, e hoʻomaikaʻi hou aku i nā kumukūʻai ma ka hōʻemi ʻana i ka ʻōpala a me ka hoʻēmi ʻana i ka pono no nā mea pono hou aʻe.

3. Ka hoʻohana ʻana o ka paipu wili i hoʻopili ʻia:

3.1 Nā Hale a me nā ʻOihana Hana:

Hoʻohana nui ʻia nā paipu wiliwili i ka ʻoihana kūkulu hale, ʻoi aku hoʻi i nā papahana nui. Hoʻohana pinepine ʻia lākou e hana i nā hale kolamu, kaola a me nā hale pou. Ma muli o kona ikaika kiʻekiʻe, hiki iā ia ke kū i nā ukana kaumaha a kū i nā ikaika ʻaoʻao, e kūpono ai no ke kūkulu ʻana i nā alahaka, nā hale kiʻekiʻe a me nā kahua hohonu.

3.2 ʻOihana ʻaila a me ke kinoea:

Ma ka ʻāpana aila a me ke kinoea, hoʻohana nui ʻia nā paipu wiliwili no ka lawe ʻana i nā huahana petroleum, ke kinoea kūlohelohe a me nā wai ʻē aʻe. ʻO ka hiki o ka paipu ke kū i nā wahi kaomi kiʻekiʻe, ke kūpono no nā noi kai hohonu a me ke kūpaʻa ʻana i ka palaho e lilo ia i koho mua no nā pipelines, nā risers a me nā hoʻonohonoho ma waho.

3.3 ʻEnekinia Mīkini:

Hoʻohana ʻia nā paipu wiliwili i hoʻopaʻa ʻia i loko o nā ʻano hana like ʻole i ka ʻenekinia mīkini a kū i waho no ko lākou kūpaʻa a me ka versatility. Hoʻohana ʻia lākou i ka hana ʻana i nā mīkini, nā ʻōnaehana halihali a me nā ʻāpana kūkulu. Eia kekahi, he kuleana koʻikoʻi ko lākou i ka ʻoihana kaʻa, e hāʻawi ana i ke kākoʻo kūkulu holoʻokoʻa i ka mōlina a me ka ʻōnaehana hoʻopau.

I ka hopena:

I ka hoʻomau ʻana o ka ʻoihana e ulu nei, ke ulu nei ka pono no nā hopena paʻa, paʻa a me ke kumukūʻai kūpono. Hoʻokō pono nā paipu wili i hoʻopaʻa ʻia i kēia mau pono a lilo i waiwai nui ma nā ʻano he nui. ʻO ko lākou ikaika kiʻekiʻe, ke kūpaʻa i ka pala a me ke kumukūʻai kūpono e hoʻopaʻa hou i ko lākou kūlana ma ke ʻano he koho mua no nā ʻano noi ʻenekinia like ʻole. I ko mākou neʻe ʻana i mua, ua maopopo e hoʻomau ka paipu wili i ke ʻano o ka wā e hiki mai ana o ka ʻoihana hou.